Introducing IFMA’s podcast Connected FM! We are excited to share the latest insights and ideas in facility management from industry insiders. On our first episode, Graziella Sicilliano from the US Department of Energy interviewed Greg Lamson from Boston Scientific to talk about energy management and the ISO 50001 global standard.

They also discussed what’s driving energy and carbon management at Boston Scientific and how using the ISO 50001 energy management system framework is helping streamline efforts across the company saving energy, carbon, time and money. Efficient energy management is crucial for enhancing resilience against fluctuating energy costs, reducing expenses, and promoting sustainability, and ISO 50001 provides a structured approach to achieve this.

ISO management system standards play a significant role in the certification process for ISO 50001. While certification is not mandatory, it demonstrates to external parties that organizations have effectively implemented an energy management system.

What is ISO 50001 and Energy Management?

ISO 50001 is an international standard for energy management systems (EnMS) that provides a comprehensive framework for organizations to establish, implement, maintain, and continually improve their energy management practices. Essentially, energy management involves a systematic approach to optimizing energy use and consumption within an organization.

The primary goals are to reduce energy costs, enhance energy efficiency, and minimize environmental impact. By adopting an energy management system, organizations can significantly improve their energy performance, reduce greenhouse gas emissions, and bolster their reputation for sustainability. ISO 50001 helps organizations not only manage their energy use more effectively but also demonstrate their commitment to environmental stewardship and operational excellence.

Here's a quick recap of our top 5 favorite moments from the episode:

1. How do you get FMs and leaders to move toward carbon neutrality and reduce greenhouse gas emissions?

“It's a top-down approach,” said Lamson. “Everybody's performance metrics are tied to these goals. We have social and sustainability goals as well as environmental. We have a global facilities and utility management team. We meet every month or every other month and that's how we stay in contact through community of practice. Just lots of knowledge sharing. It's definitely a great resource.”

2. How did you implement and coordinate adoption of the ISO 50001 energy management system?

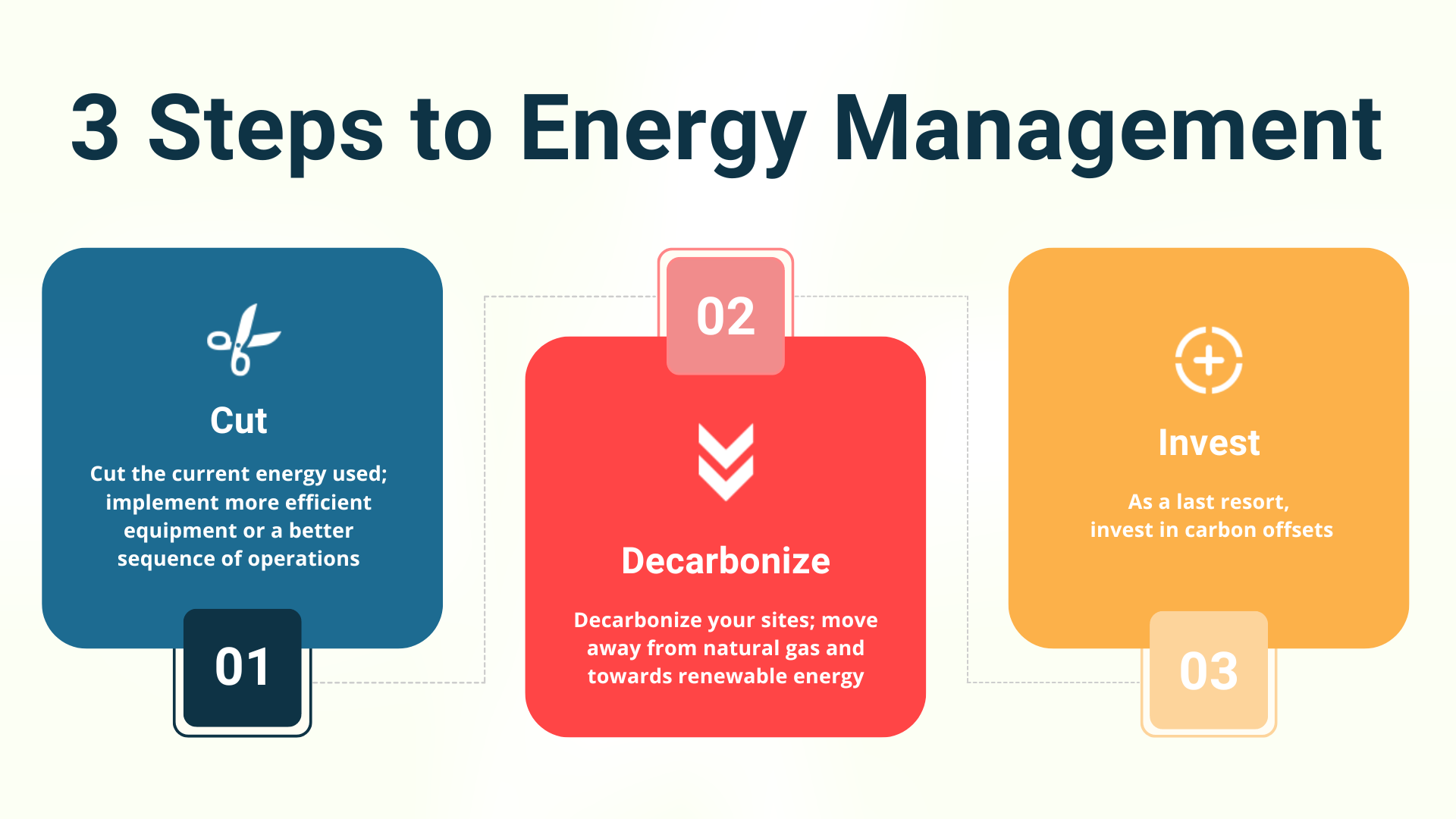

“Energy management is going to be our key tool to implementing carbon neutrality,” said Lamson. “We have basically three pillars of that: cut, convert and compensate.”

ISO management system standards provide guidelines and requirements that help organizations set up and operate energy management systems, showcasing their practical applications.

Step 1: Cut the current energy used; implement more efficient equipment or a better sequence of operations

Step 2: Decarbonize your sites; move away from natural gas and towards renewable energy

Step 3: Invest in carbon offsets

3. What were the challenges and benefits of implementation?

Efficient energy management can help organizations overcome challenges related to fluctuating energy costs and maximize the benefits of ISO 50001 implementation by providing a structured approach to improve energy use and manage their energy impact effectively.

“We had a lot of experience behind us. Our sites in Ireland and Prague were already 50001 certified so they built the energy manual. Certainly being able to use all the tools that have been put in place, really allowed us to meet our goal,” said Lamson.

“We do know a lot of European companies that have a lot of incentives in Europe (financial)…that we don’t quite have setup in the United States,” added Sicilliano.

As for benefits, Lamson said that prior to the 50001 certification, “Our energy management was more of an ad hoc type situation…it wasn’t strategic at that point…It wasn’t as standardized.”

4. What are your next steps?

“It’s an ongoing process. We are always trying to improve the program, implement more efficient equipment, but in general just improve the program,” said Lamson. “One of my favorite sayings is ‘Continual improvement.’”

Efficient energy management plays a crucial role in this continual improvement, helping to enhance resilience against fluctuating energy costs, reduce expenses, and promote sustainability.

5. What is your most helpful tool?

“ISO 50001 Energy Footprint Guide. I find that is THE most important tool we have,” said Lamson.

ISO management system standards provide a framework for using tools like the Energy Footprint Guide effectively.

Achieving Efficiency and Sustainability with ISO 50001

Implementing ISO 50001 can lead to substantial benefits for organizations, including enhanced energy efficiency, reduced energy consumption, and lower energy costs. By establishing a robust energy management system, organizations can pinpoint areas for improvement, set clear energy performance indicators, and devise strategies to continually improve their energy management practices.

ISO 50001 also facilitates the integration of energy management with existing management systems, such as quality management systems and environmental management systems. This integrated approach allows organizations to optimize their energy use, minimize waste, and improve their overall sustainability performance. By leveraging the ISO 50001 framework, organizations can achieve a more efficient and sustainable operation, aligning their energy management efforts with broader environmental and quality management goals.

Conclusion

In conclusion, ISO 50001 is a powerful tool for organizations seeking to improve their energy management practices, reduce their environmental impact, and enhance their sustainability credentials. By implementing an energy management system, organizations can achieve significant benefits, including improved energy efficiency, reduced energy consumption, and lower energy costs. With its modular structure and compatibility with other management system standards, ISO 50001 provides a flexible and integrated approach to energy management that can be tailored to meet the needs of organizations of all sizes and sectors.