Every facility manager who wants to improve job performance knows the key is tracking KPIs or Key Performance Indicators. With the wide variety of facilities and unique problems that come with managing complex structures, how do FMs know what KPIs to track?

Facility management KPIs are essential for tracking and measuring the performance and effectiveness of various aspects of facility operations. Facilities management metrics, on the other hand, are single data points with no objective, unlike KPIs, which show how well a facility is meeting its objectives.

Facilities management software plays a crucial role in tracking KPIs and other metrics, reporting, visualizing data, and streamlining processes related to maintenance management and facility KPI performance.

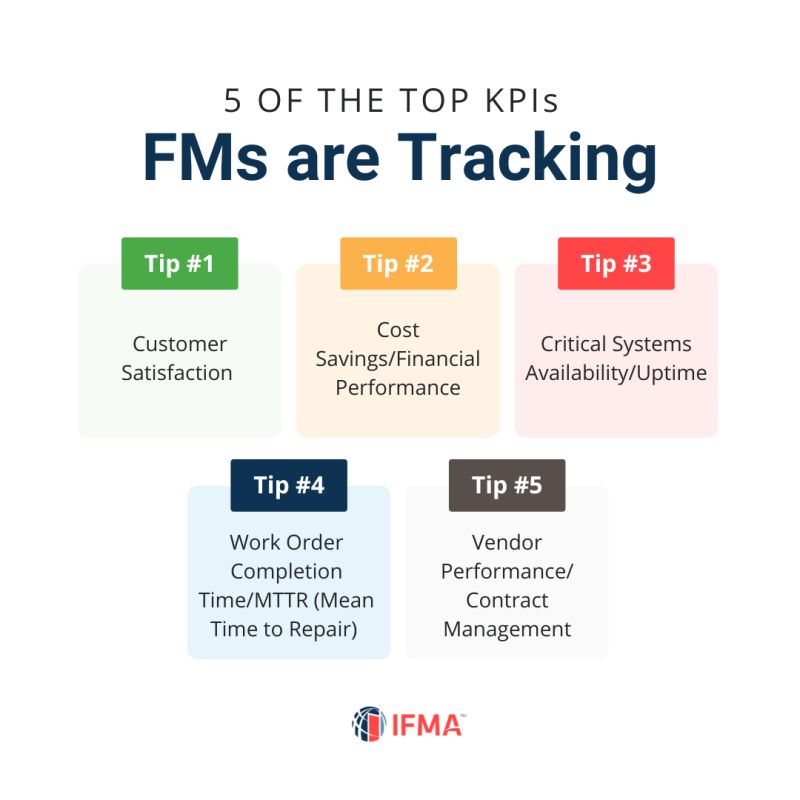

To get a better understanding, we asked our LinkedIn community, “What metrics are you tracking? What KPIs are important to you?” Here are some of their top answers:

Client satisfaction is one of the key performance indicators

-

“The most important one: “Client Satisfaction”. Facility managers play a crucial role in tracking client satisfaction as a KPI.”

—Luis Morejon, Global Facility Management Lead at Newmark, IFMA Global Board of Directors

-

“We can divide KPIs into a few groups such as customer satisfaction, maintenance, operation, and finance. KPIs would be set up to measure the success and execution of the company’s specific goals and objectives. You can use operations and maintenance-related KPIs such as system or service availability, MTTR, MTBF - these will serve as a trigger to dive deeper. The ones very “popular” demonstrating the health of the maintenance is the ratio between preventative and demand maintenance and actual attainment of the maintenance etc. Facility operations are measured using KPIs like MTTR and MTBF to assess their effectiveness.”

—Iouri M., Manager, Operations & Maintenance, Oakland Airport Connector at Doppelmayr USA

Most facility managers look at team cohesion

-

“For years I’ve mentored my reports to think of FM as a 3-legged stool that you are trying to balance on. One leg is financials, the second is customer satisfaction, and the third is internal team cohesion. I have never seen a maintenance operation excel at the first two when they lack the third. Gross facilities management costs significantly impact financial performance.”

—Martin Luckcuck, CEO at NKW Corporation

-

“Customer satisfaction, work order completion time, energy consumption. Key performance indicators (KPIs) are crucial for tracking energy consumption.”

—Melody Atim, Facilities Manager at Stanbic Properties Limited

-

“Customer satisfaction, utilities expenses (power/water/etc.), cost /square.ft., equipment or asset availability. Maintenance costs impact the cost per square foot.”

—Oswald Vincent, CFM, Facilities Manager at Emaar

-

“As built environment managers, my key KPI to measure is a. User experience satisfaction and b. Maintenance cost savings. These matter most to me because, when my direct users like stakeholders, tenants/occupiers have assurance in the money spent to maintain and I can handle it efficiently. This is my ultimate success. The maintenance team plays a crucial role in achieving maintenance cost savings.”

—Tomisin Kamiyo, Facilities and Operations Manager at Reidius Design

Facility management KPIs: Preventive maintenance compliance

-

“Preventive maintenance schedule tracking and completion, project (renovation and innovative solution implementation) completion percentage, complaint tracking and closeout rate, facilities utilization, cost saving, vendor performance review. Operational costs impact project completion rates.”

—Thein Win Aung, Manager at ATOM

-

“Work order completion time—which ultimately leads to better customer satisfaction. Number of open work orders, number of work orders on hold, how many PMs completed month to date. Preventive maintenance compliance impacts work order completion time.”

—Chris VanDruff, Vice President of Facilities Services at Maxwell Group, Inc.

-

“Technician’s performance based on their ppm and troubleshooting targets and how they solved at what time they took to complete their targets based on costs and service charges. Apply it to individual machines or (utilities systems) and calculate it monthly and quarterly. Preventive maintenance tasks are crucial for achieving troubleshooting targets.”

—Fasahat Hussain, Mechanical Site Engineer at Growmore Technical Services LLC

-

“In my current portfolio, I am tracking the following—1. Financials Performance (ie variances on Budget vs Actual for OPEX and CAPEX) 2. Critical Equipment Performance (ie 100% Genset, UPS, FM200, CCTV, Access Control Reliability). 3. Facilities Management and Innovation (ie SLA of FM ticketing system, workplace safety and improvement project initiated and completion within timeline, budget and impact towards operation and company’s benefits). 4. Internal Process and Compliance 5. People (ie employee’s coaching and performances, development by attending/sending to trainings and well being). Reactive maintenance impacts critical equipment performance.”

—Elsie Marie D-Lim Lee, Facilities Management - Malaysia at TaskUs

Maintaining an ideal reactive maintenance ratio is crucial in facility management to prioritize preventive tasks and save time and money. Additionally, tracking utility costs is essential for improving financial performance and sustainability.

Editor’s Note: Some comments from this post have been edited for clarity or brevity. Thank you to our amazing online community for their contributions and their commitment to knowledge sharing.